Increased productivity through optimised material selection

The microscope stages from ITK’s TargetPrecisioner® family are customised according to the wishes of numerous customers. The choice of material also plays an important role. It helps the microscope stage to reach its stable operating temperature more quickly and experiments can be started earlier. This significantly increases the user’s productivity.

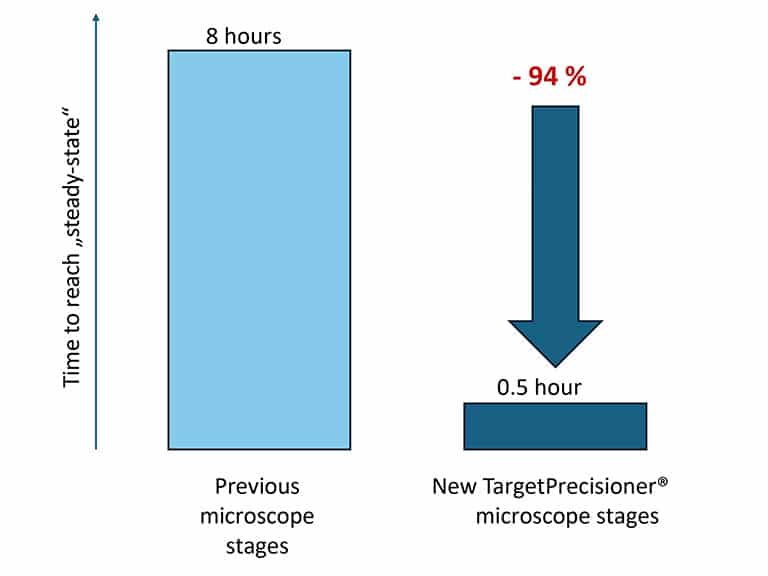

Microscope stages are often made from aluminium or steel plates. However, if they are operated dynamically in frequently changing temperature ranges, it is necessary to use an alternative material with a lower coefficient of thermal expansion. Reaching the ‘steady state’ in the incubator is realised an order of magnitude faster than with conventional materials.

In order to minimise the dependence of the TargetPrecisioner® on the external ambient temperature, tests were carried out with various materials and material pairings. Titanium proved to be a particularly suitable material.

Titanium exhibits less expansion and distortion in higher temperature ranges and during rapid temperature changes. The ‘steady state’ for the microscope stage is reached after around 0.5 hours, which significantly reduces the temperature-related Z drift. Furthermore, the influence of the coefficient of thermal expansion is also becoming more important. Titanium is also characterised by a lower weight compared to steel with the same volume, which guarantees the high traversing speeds of the highly dynamic TargetPrecisioner®. The in-house production of titanium plates can be flexibly adapted to individual customer requirements.