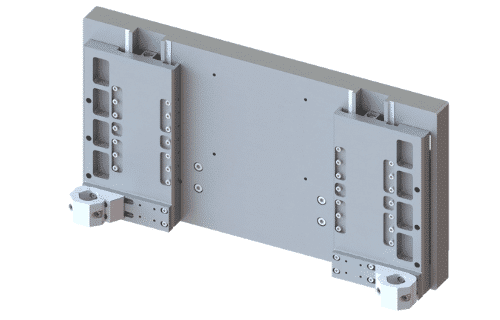

POSITIONING SYSTEMS

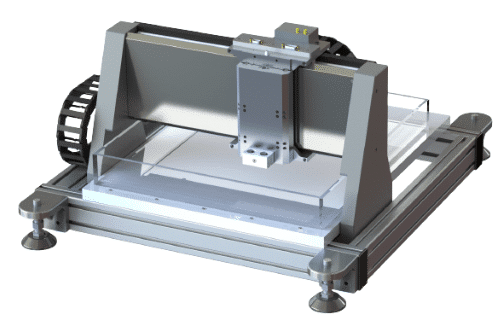

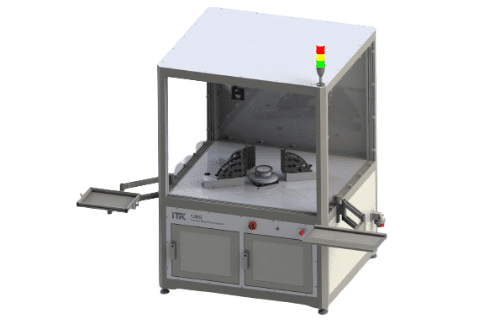

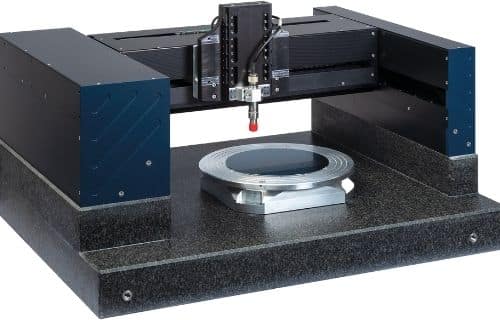

All core elements of our positioning systems such as electronics, mechanics and software are developed in-house at ITK. This enables us to supply high-precision and efficient positioning systems at the highest technical level for industry and research, not just modularly from a construction kit, but customised.

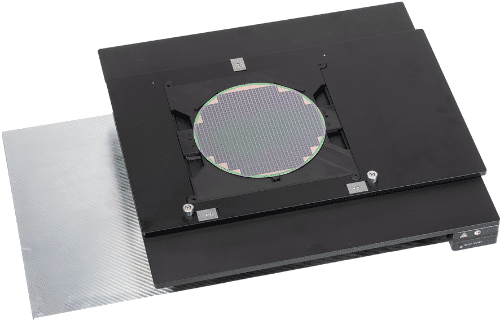

MODULES

Our positioning systems can be optionally expanded with various (high-speed) Z-axis modules. Of course, you can also get the matching measuring system from us. The assembly of the required Z-axes can be done by the customer, but of course we are also happy to supply you with a complete solution.

COMPONENTS

We develop control technology for all common motor variants for positioning mechatronic applications. The focus is on dynamic and precise fine positioning down to the nanometre range. Our products bring decisive advantages in terms of speed, dynamics, maximum precision and reliability