We know all about that.

Also for your industry!

OEM Machines

01

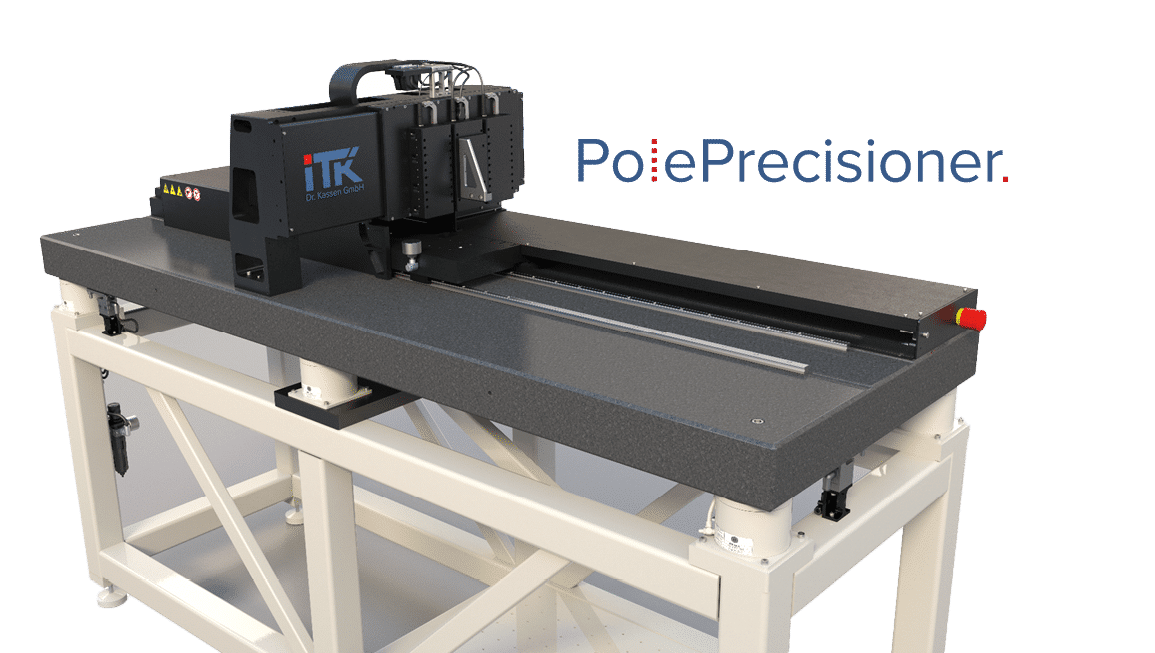

The reason for the production of our first magnetising system for writing on scales fits into one word: Own demand! The commissioning of the plant over 20 years ago was the birth of a new business field for ITK. Since then, the demand for solutions from OEM customers has increased year after year. We meet this demand with high-precision, high-performance systems – developed and approved in accordance with the Machinery Directive. Today, a team of experts from various disciplines at ITK implements special projects based on the pillars of “Positioning. Measure. Control. Move.” are the cornerstones. Our “PolePrecisioner” product family includes rotary as well as linear magnetising systems.

Mit dem Laden des Videos akzeptieren Sie die Datenschutzerklärung von YouTube.

Mehr erfahren

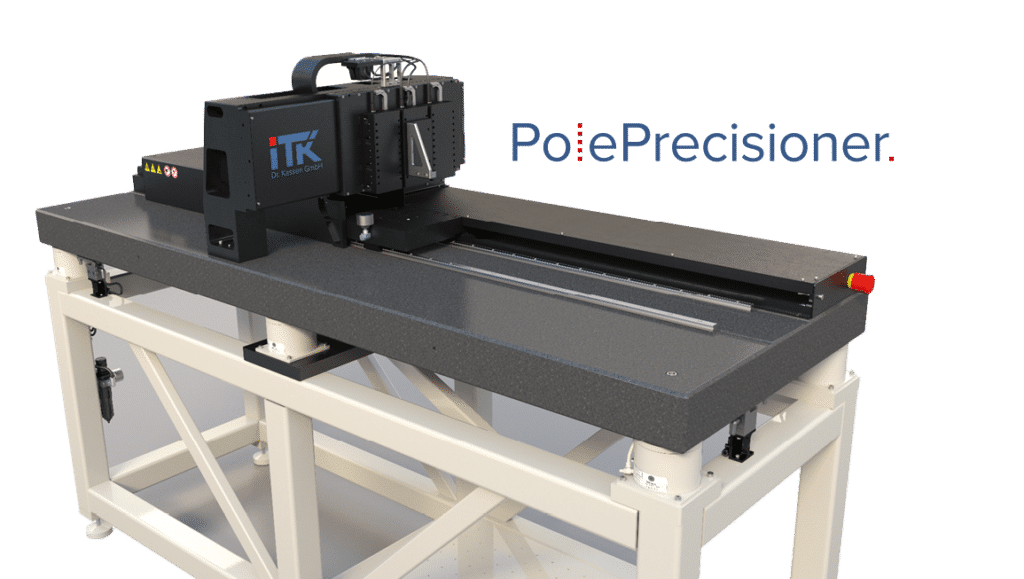

Magnetisers from ITK belong to the PolePrecisioner® product family.

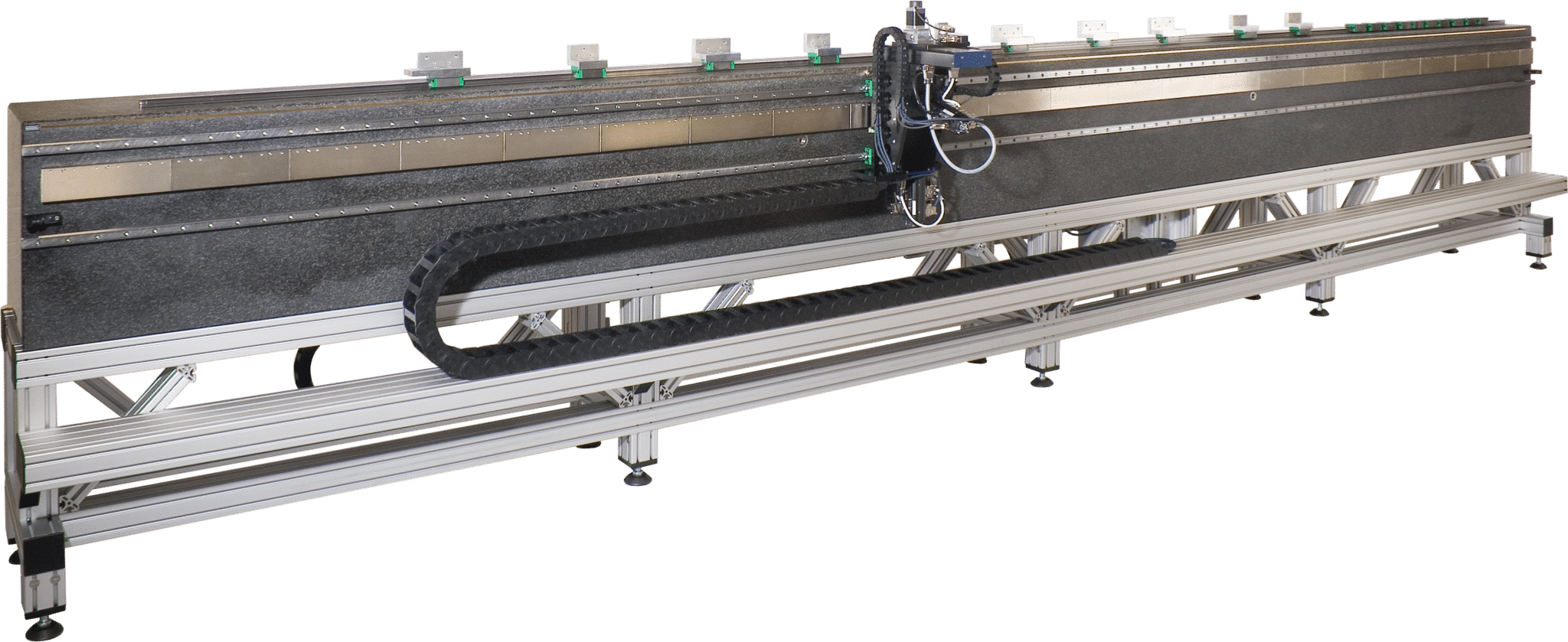

The linear magnetisers from the LMP family can be used to describe scale materials made of different materials. These include.

The magnetising system is designed for flexibility. Basically, scale lengths can be written in the standard variant from 50 mm up to 5000 mm; other lengths are possible on request. Do you want to produce scales with different magnetic and geometric properties? No problem: The interchangeability of the write and read heads offers you almost unlimited possibilities, all of which you can use with just one system. The magnetising systems are preferably equipped with positioning axes in linear motor technology and ITK’s own measuring systems. Spindles for locomotion are dispensed with. This offers additional convincing advantages:

The use of a laser interferometer reference measuring system allows the “poles” to be stamped into the scale material with a high degree of accuracy – reproducibly. A high reject rate is avoided – the best prerequisite for opening up new fields of application.

We manufacture our systems according to customer specifications. On request, we can provide you with a turnkey solution according to your specification. This can look as follows:

LMP magnetizing system included:

Mit dem Laden des Videos akzeptieren Sie die Datenschutzerklärung von YouTube.

Mehr erfahren

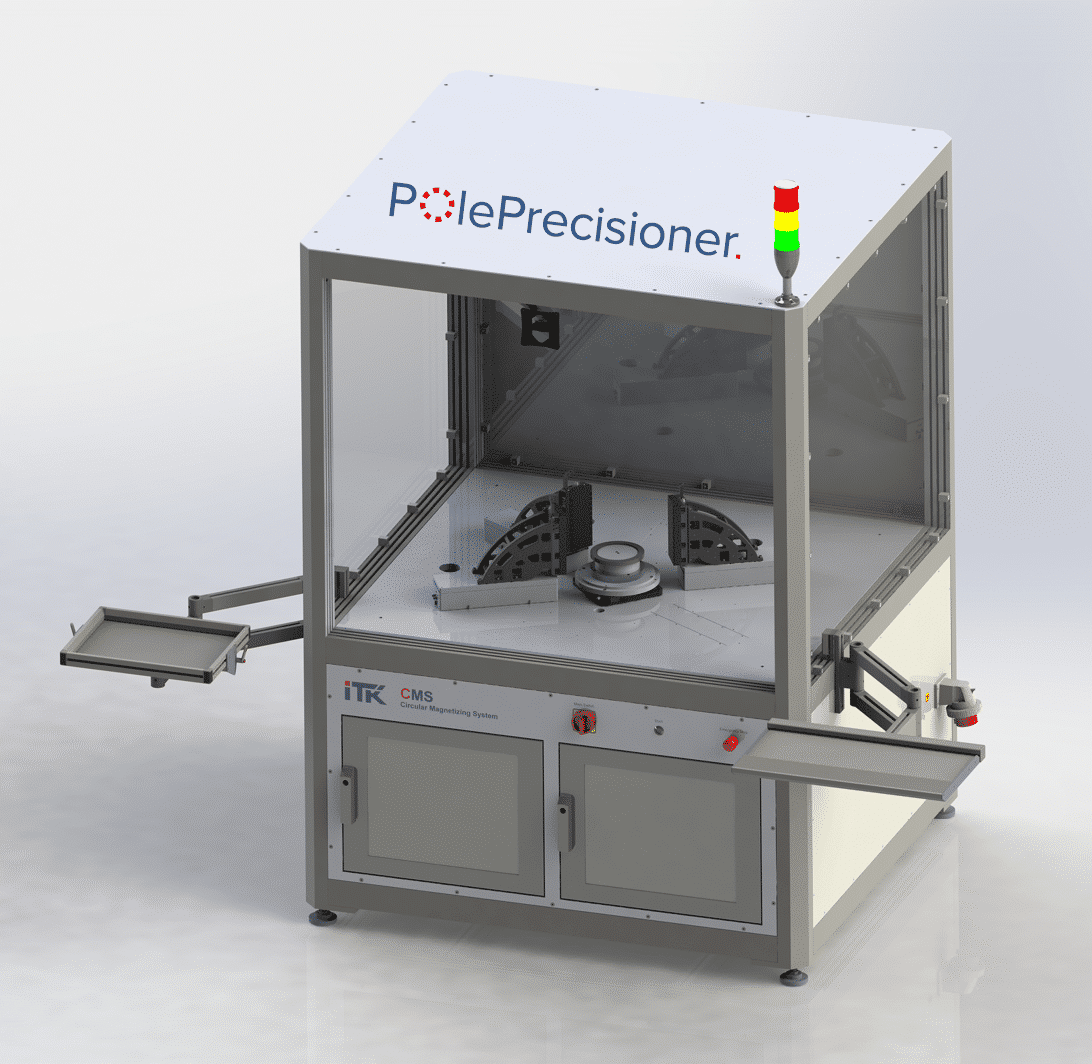

Magnetisers from ITK belong to the PolePrecisioner® product familiy.

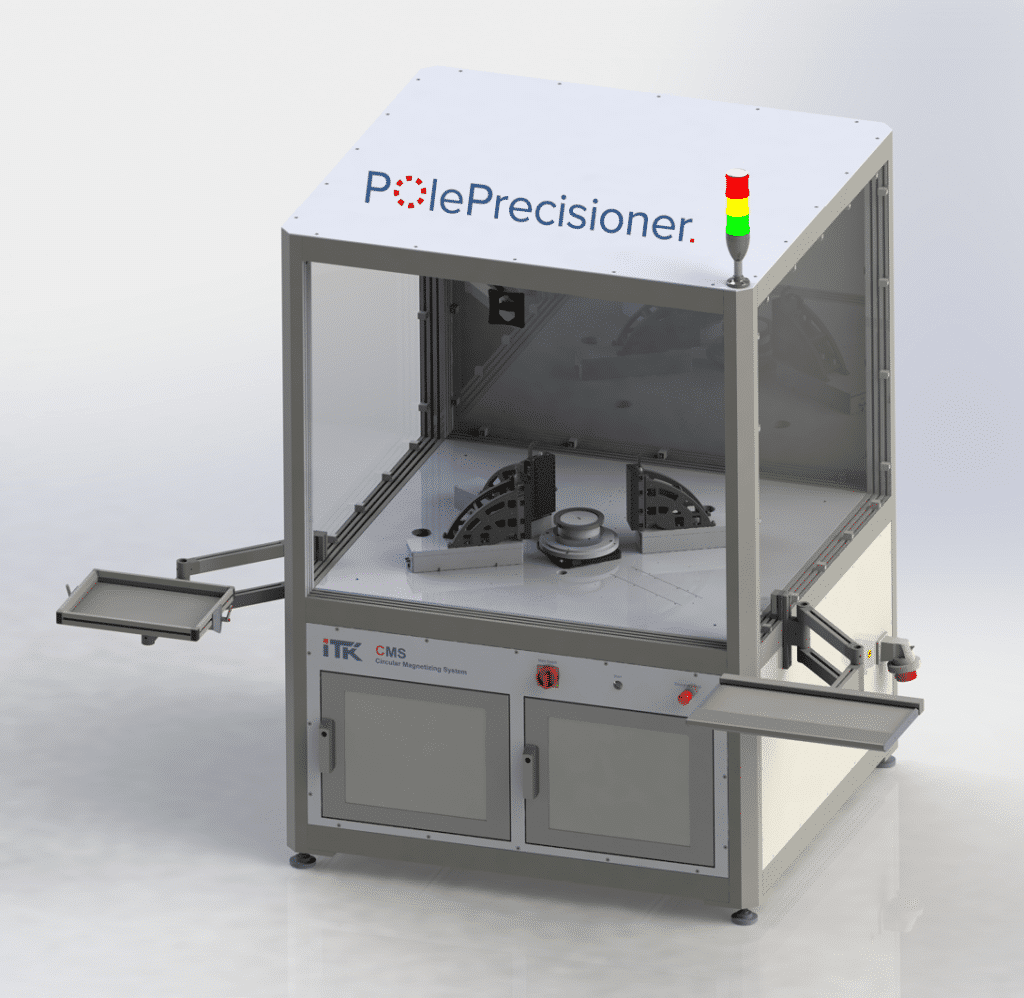

As with the LMP family, materials made of hard magnetic, elastomer- and plastic-bonded materials can also be described with the rotary magnetising systems. The poles can be arranged radially or axially.

With the RMP magnetising system you can generate scales with different diameters – and this in a wide range. The clamping systems can be exchanged without any problems. So you can realize diameters between 20 and 200 mm (as standard, other diameters on request) in no time. By using a high-precision encoder system as a dimensional standard, the poles can be stamped into the scale material with a high degree of accuracy. The result: scales with high accuracy can be produced reproducibly.

Once the writing process is complete, each individual scale can be clearly marked. Barcodes can be applied directly to the scale for this purpose. Your advantages:

Proven products. Proven know-how.

A magnetising system is only as good as its components. That’s why we only use high-quality, tried-and-tested products. You can rely on that. Benefit from almost 40 years of know-how in the development and manufacture of complex positioning systems and MR measuring technology. This will certainly give you a good feeling!

We manufacture our systems individually for each customer. On request, we can provide you with a turnkey solution according to your specification. This can look as follows:

RMP magnetising system included:

Are you interested in a special machine for a precise positioning task, tailored exactly to your current needs? Then contact us! We have the possibility to manufacture customised special machines for you and will be happy to implement your ideas together with you.

All core elements of our positioning systems such as electronics, mechanics and software are developed in-house at ITK. This enables us to supply high-precision and efficient positioning systems at the highest technical level for industry and research, not just modularly from a construction kit, but individually adapted.

ITK Dr. Kassen GmbH

Beim Eberacker 3 | D-35633 Lahnau

SIE MÖCHTEN AUF DEM LAUFENDEN BLEIBEN?

DANN ABONNIEREN SIE UNSEREN NEWSLETTER!

YOU WANT TO STAY UP TO DATE?

THEN SUBSCRIBE TO OUR NEWSLETTER!

Technical Data

Parameters | Typical performance characteristics |

|---|---|

Scale lengths | 50 - 5000 mm (as standard; other lengths on request) |

Materials | hard magnetic, elastomer-bonded and plastic bonded material |

Track widths | 1 - 5 mm |

Number of tracks | 1 - 3, several coded tracks possible |

Period lengths | 500 - 5000 µm |

Accuracy | up to the sub-µm range (compensated) |

Resolution | in the nanometre range |

Writing method | digital or analogue |

Software | customised operating and evaluation software |

Quality inspection | scale measurement on the same system |

Typical operating conditions | industrial continuous operation (24/7) |

Labelling | each scale can be individually marked |

Technical Data

Parameter | Typical performance characteristics |

|---|---|

Scale diameter | 20 - 200 mm (as standard; other diameters on request) |

Scale materials | hard magnetic, elastomer and plastic bonded material |

Coding placement | optional radial or axial description |

Number of lines | freely selectable |

Number of tracks: | several coded tracks possible; reference marks (polarisation adjustable) |

Repeatability: | from 5 arcsec (depending on reference measuring system and material) |

Resolution | up to 0.5 arcsec |

Writing method | digital or analogue |

Software | customised operating and evaluation software optional |

Quality inspection: | scale measurement on the same system optional |

Typical conditions of use | industrial continuous operation (24/7) |

Marking | each scale can be individually labelled. |

The PolePrecisioner® product family includes our magnetizing systems, which we offer as RMP Rotary Magnetizing systems and LMP Linear Magnetizing systems. In these systems, magnetic pole patterns are applied to measuring scales (pole rings or linear scales). The trademark is made up of Pole or magnetic pole, Precision and Positioning.