We know all about that.

Also for your industry!

Modules

03

The modular design of all ITK systems is the basis of our flexibility. Our assemblies are subdivided according to the type of movement. The three superordinate assembly categories result in a wide range of linear tables, cross tables and rotary tables. In this context, the interaction with the ITK controls developed in-house should be emphasised.

The control technology is our origin and the decisive factor in exploiting the full performance potential of the mechatronic assemblies. Talk to us about how our in-house software and electronics development can implement your special requirements in a customised way.

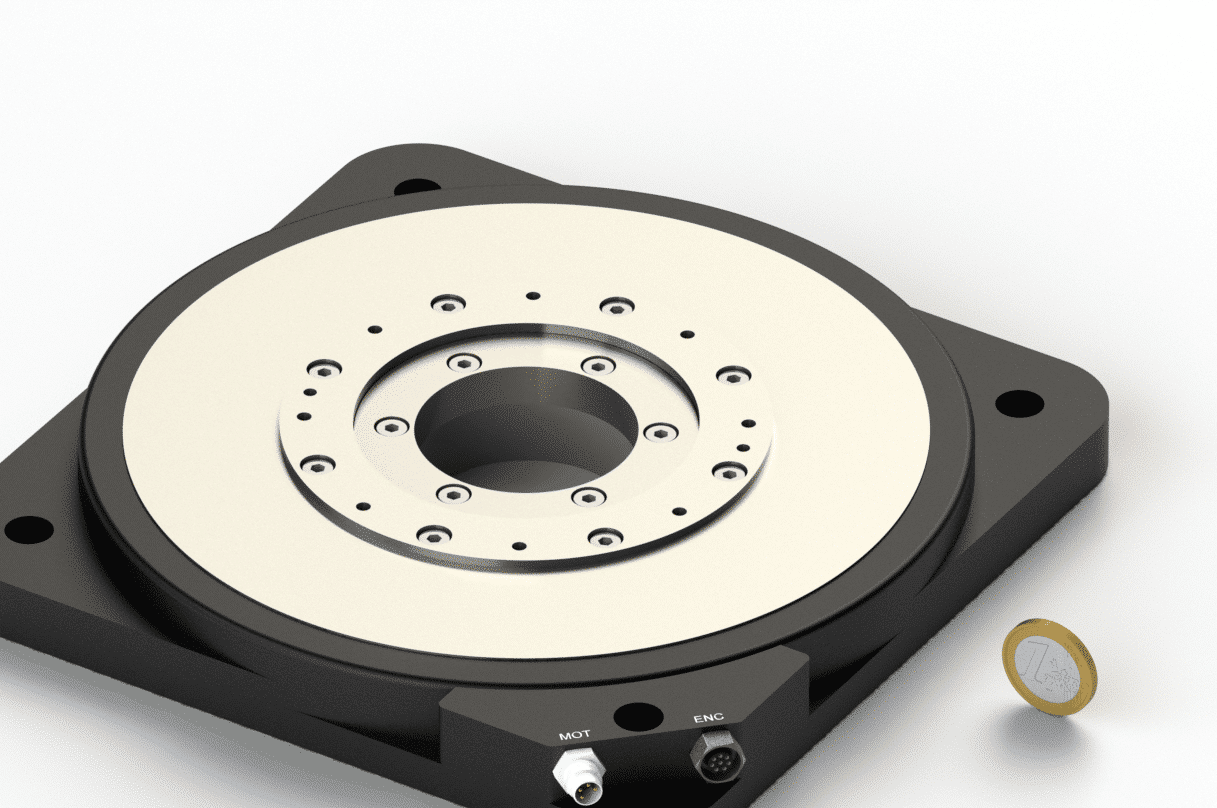

The extremely flat rotary tables with very high demands on axial run-out, concentricity, repeatability and overall height are among the absolute top class on the market. The central hollow shaft for the feed-through of cables, vacuum or connectors also proves to be particularly advantageous. The rotary tables are intended for applications in the optical industry for measuring and bonding lenses, in measuring machines of all kinds, wire bonding machines or in the semiconductor industry in inspection systems for testing wafers.

Product | Repeatability | Axial run-out | Concentricity | Mass to be moved | Hollow Shaft | Diameter (in mm) |

|---|---|---|---|---|---|---|

FRS Flat Rotary Stage | ■ ■ ■ | ■ ■ | ■ ■ | ■ ■ ■ | ■ ■ ■ | 100, 200 |

RS Rotary Stage | ■ | ■ ■ ■ | ■ ■ ■ | ■ ■ | ■ ■ ■ | 50, 100, 200, 250, 300 |

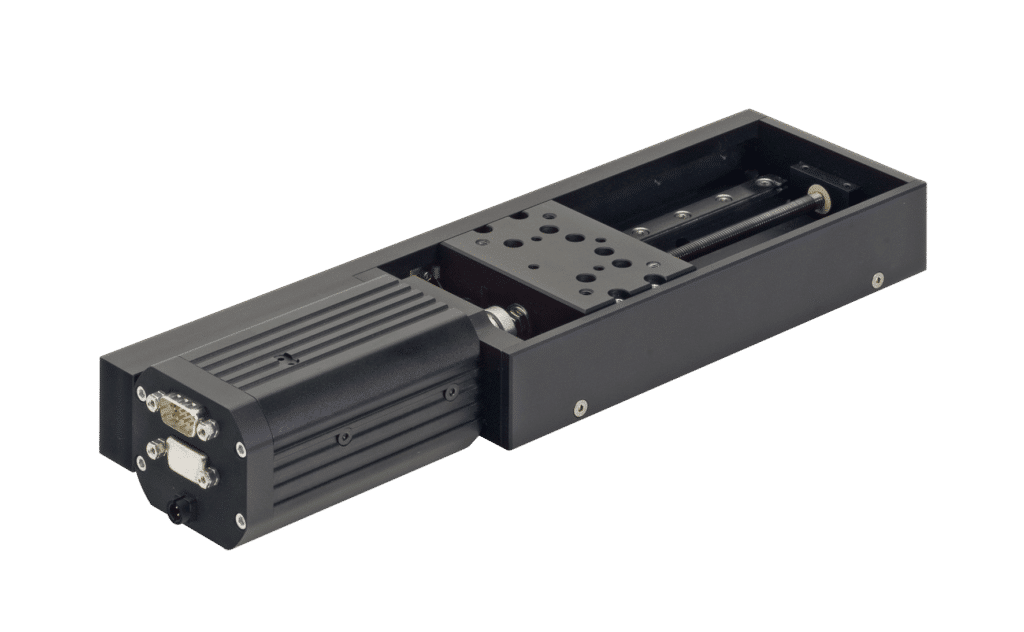

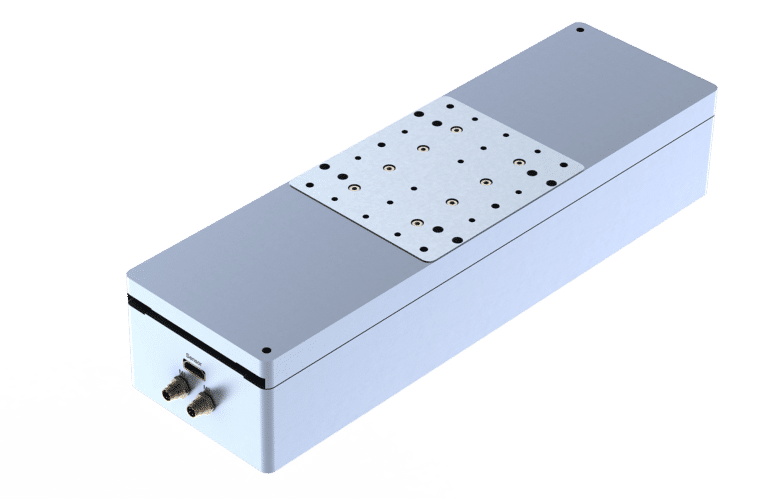

Precision, dynamics and long-term stability form the basis for high throughput rates and reliable operation. Thanks to a new type of linear motor, they are a good alternative to spindle or piezo drives. They are supplied with powerful controllers and other accessories and offer unsurpassed precision. High-quality guides ensure optimum rigidity, damping and running accuracy, resulting in unsurpassed precision.

Product | Repeatability | Travel Speed | Acceleration | Mass to be moved | Travel Path |

|---|---|---|---|---|---|

FLS 100 | ■ ■ ■ | ■ ■ ■ | ■ ■ ■ | ■ ■ | ■ ■ ■ |

LS | ■ ■ | ■ ■ | ■ ■ ■ | ■ ■ ■ | ■ ■ ■ |

ST9 Eco | ■ | ■ | ■ ■ | ■ ■ ■ | ■ ■ ■ |

STK 50 | ■ | ■ | ■ | ■ | ■ |

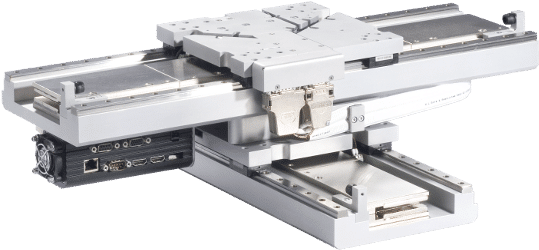

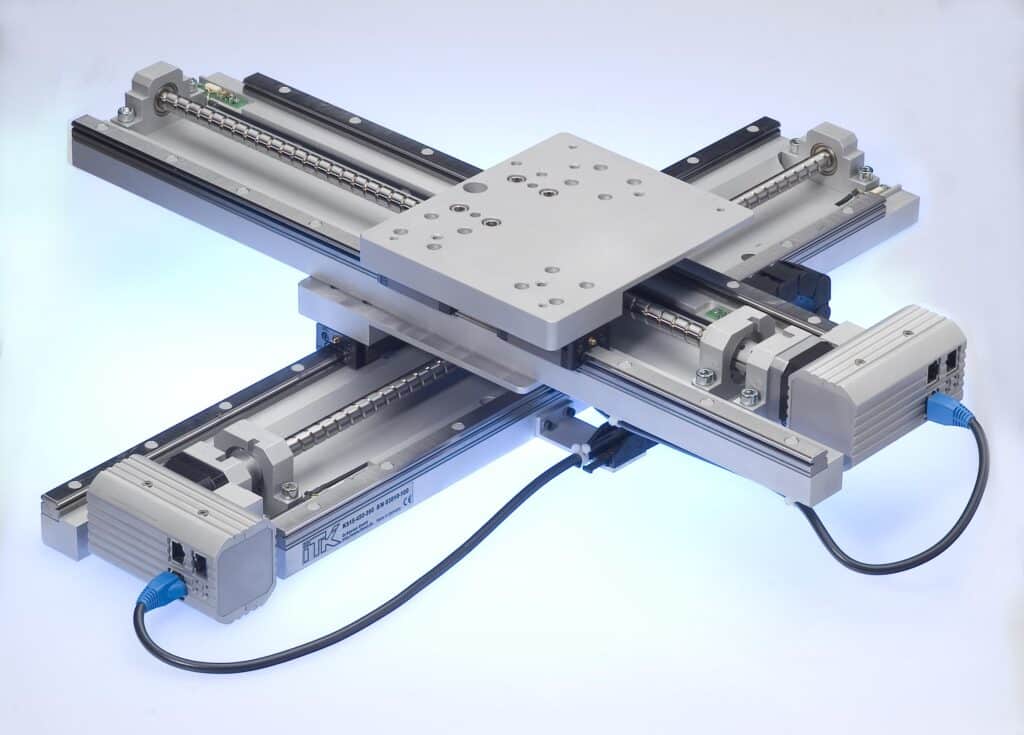

Cross stages from ITK are extremely compact, flat and designed for different travels and accuracies.

Product | Repeatability | Travel Speed | Acceleration | Mass To Be Moved | Travel Path | Basic Technology |

|---|---|---|---|---|---|---|

FCS - ABC (Flat Cross Stage) | ■ ■ ■ | ■ ■ ■ | ■ ■ ■ | ■ ■ | ■ ■ | FLS |

KL - XY - ABC (Cross Stage Linear) | ■ ■ | ■ ■ | ■ ■ ■ | ■ ■ ■ | ■ ■ ■ | LS |

KS - XY - ABC(Cross Stage Spindle) | ■ | ■ | ■ ■ | ■ ■ ■ | ■ ■ ■ | ST |

ABC = travel: typically 100 mm

XY: track width of the guide, typically 9, 12, 15 mm

ITK Dr. Kassen GmbH

Beim Eberacker 3 | D-35633 Lahnau

SIE MÖCHTEN AUF DEM LAUFENDEN BLEIBEN?

DANN ABONNIEREN SIE UNSEREN NEWSLETTER!

YOU WANT TO STAY UP TO DATE?

THEN SUBSCRIBE TO OUR NEWSLETTER!

Technical Data

Parameter | Unit | Typical performance characteristics |

|---|---|---|

Repeatability | arcsec | 2 … 36 |

Axial runout | µm | 3 … 10 |

Radial runout | µm | 3 … 20 |

Mass to be moved | kg | 5 … 10 |

Hollow shaft | mm | 40 … 50 |

Diameter | mm | 100, 200 |

Technical Data

Parameter | Unit | Typical performance characteristics |

|---|---|---|

Repeatability | arcsec | 2 … 36 |

Axial runout | µm | 3 … 10 |

Radial runout | µm | 3 … 20 |

Mass to be moved | kg | 5 … 10 |

Hollow shaft | mm | 40 … 50 |

Diameter | mm | 50 … 300 |

Technical Data

Parameter | Unit | Typical performance characteristics |

|---|---|---|

Repeat accuracy | µm | 0.1 … 50 |

Traversing speed | mm/s | 0.01 … 5000 |

Acceleration | mm/s2 | 100 mm/s2 … 5 g |

Position resolution | nm | 5 … 1000 |

Travel path | mm | 10 … 10.000 |

Technical Data

Parameter | Unit | Typical performance characteristics |

|---|---|---|

Repeatability | µm | 0.1 … 50 |

Traversing speed | mm/s | 0.01 … 5000 |

Acceleration | mm/s2 | 100 mm/s2 … 5 g |

Position resolution | nm | 5 … 1000 |

Travel path | mm | 10 … 10000 |

Technical data

Parameter | Unit | Typical performance features |

|---|---|---|

Repeatability | µm | 0.1 … 50 |

Travel speed | mm/s | 0.01 … 5000 |

Acceleration | mm/s2 | 100 mm/s2 … 5 g |

Position resolution | nm | 5 … 1000 |

Travel path | mm | 10 … 10000 |

Technical data

Parameter | Unit | Typical performance features |

|---|---|---|

Repeatability | µm | 0.1 … 50 |

Travel speed | mm/s | 0.01 … 5000 |

Acceleration | mm/s2 | 100 mm/s2 … 5 g |

Position resolution | nm | 5 … 1000 |

Travel path | mm | 10 … 10000 |

Technical Data

Parameter | Unit | Typical performance characteristics |

|---|---|---|

Repeatability | µm | 0.1 … 50 |

Traversing speed | mm/s | 0.01 … 5000 |

Acceleration | mm/s2 | 100 mm/s2 … 5 g |

Position resolution | nm | 5 … 1000 |

Travel path | mm | 10 … 500 |

Technical Data

Parameter | Unit | Typical performance characteristics |

|---|---|---|

Repeatability | µm | 0.1 … 50 |

Traversing speed | mm/s | 0.01 … 5000 |

Acceleration | mm/s2 | 100 mm/s2 … 5 g |

Position resolution | nm | 5 … 1000 |

Travel path | mm | 10 … 500 |

Technical Data

Parameter | Unit | Typical performance characteristics |

|---|---|---|

Repeatability | µm | 0.1 … 50 |

Traversing speed | mm/s | 0.01 … 5000 |

Acceleration | mm/s2 | 100 mm/s2 … 5 g |

Position resolution | nm | 5 … 1000 |

Travel path | mm | 10 … 500 |